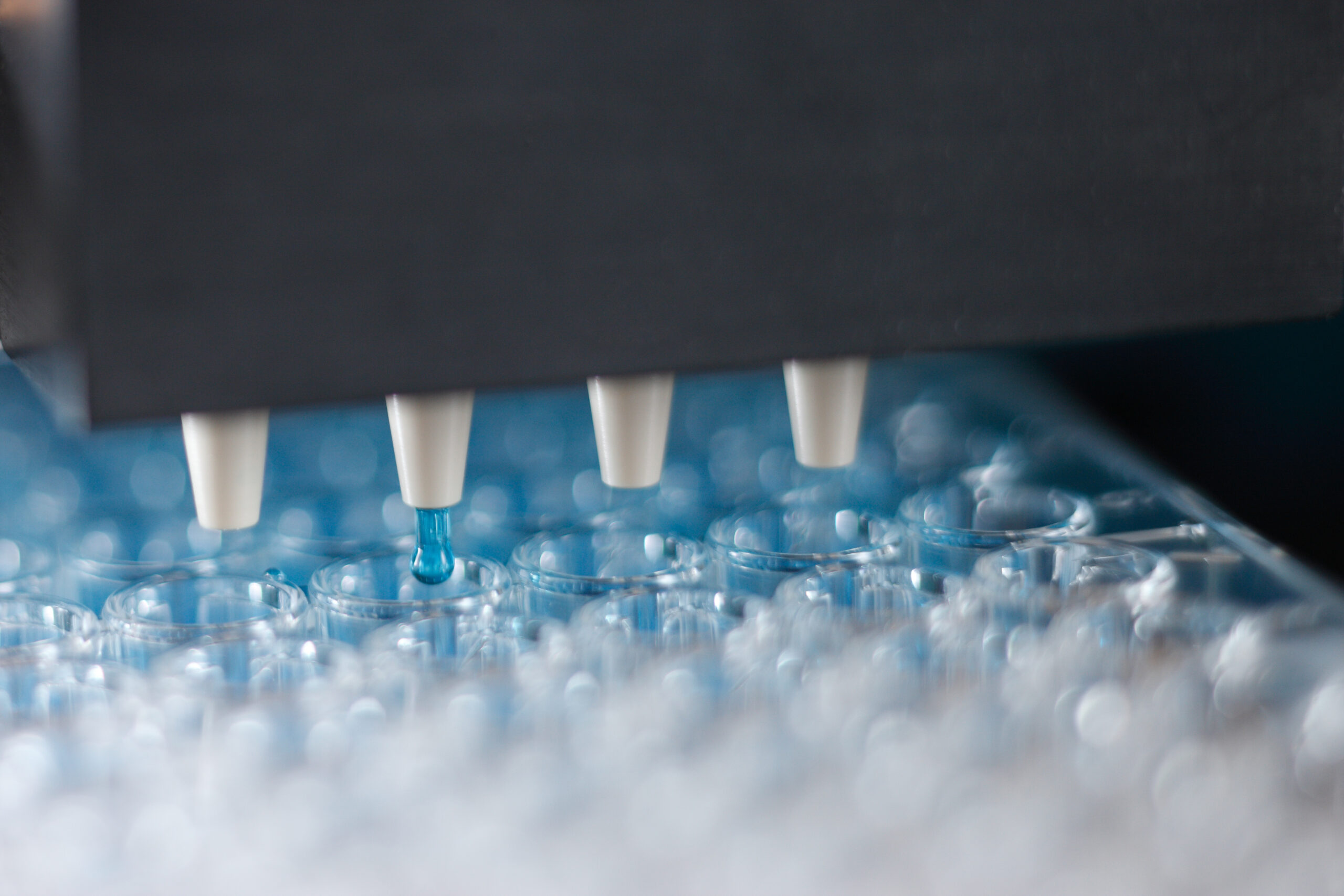

ELISA is probably the most widespread method, performed in microplates. The assay requires one or more steps of washing, dispensing, incubation, shaking and reading. It is widely used in research, food testing, diagnostics and other fields. There are several factors that make ELISA automation very desirable:

Automation solves all these problems by increasing reliability and reproducibility, increasing throughput, freeing staff from repetitive tasks and allowing them to focus on more important tasks. However, there are different forms of ELISA automation, so it is very important to choose the right instrument for the task.

Most instruments on the market offering ELISA automation have been designed to analyze immunoassays in large hospitals. This kind of equipment is capable of performing a large quantity of different assays per day, but it is bulky, expensive and requires frequent and costly maintenance. In addition, ELISA kit manufacturers very often provide these instruments to support their applications. Thus, they have little flexibility to perform assays from other manufacturers, or are sold alongside an agreement to purchase a large quantity of kits during a given period of time. Hence, they are not always the best choice for customers other than large hospitals.

All automated ELISA systems offer the basic functions needed to process an ELISA: reagent dispensing, microplate washing, incubation and absorbance measurement. But some other functions are not always available and, if you are looking to purchase a system for your laboratory, it is important to know if you require them or not:

Another important distinction is the number of samples to be processed per day: low-throughput instruments are affordable and the perfect solution for laboratories processing only a few plates per day. On the other hand, higher throughput laboratories do need more sophisticated and expensive instrumentation to perform the job.