MAXIMUM SPEED AND RELIABILITY

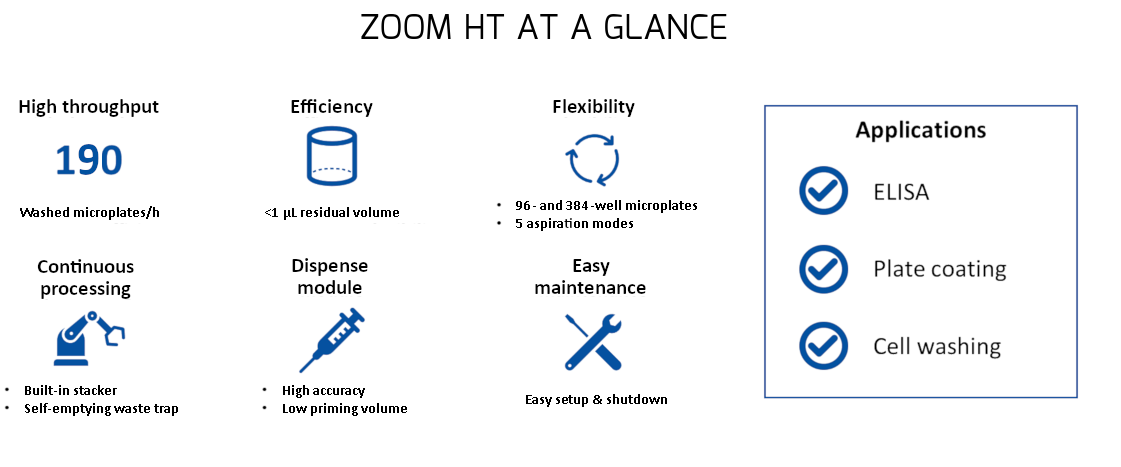

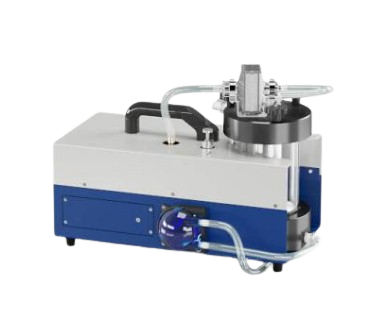

The Zoom HT microplate washer is a robust and easy-to-use system that delivers the speed you need for high throughput plate washing. The unmatched speed of the system is the result of the integrated stackers and a one-rail design. This plate washer can process both 96 and 384 well microplates without changing the wash head.

The Zoom HT microplate washer is a robust and easy-to-use system that delivers the speed you need for high throughput plate washing. The unmatched speed of the system is the result of the integrated stackers and a one-rail design. This plate washer can process both 96 and 384 well microplates without changing the wash head.

The fastest plate washer on the market today

It takes only 17 seconds for a triple wash of a 96 well microplate. Combined with the unique one-rail plate transfer design which moves the plate a very short distance from the stack to the wash position. This enables a typical throughput of 150 washed plates per hour, or up to 1050 plates per day (3 x 300 µL, 7 h per day, 1 single Zoom HT).

A single wash head for all plate types

Each wash channel has its own aspirate and dispense tip, which allows simultaneous washing of all 96 wells. The same 96 channel wash head is used for 384 well washing in four quadrants, making it unnecessary to purchase different wash heads for different plate types. Rapid positioning of the wash head provides 384 well wash speeds comparable to 384 well channel washers. Large diameter aspirate tips, 3-dimensional (3D) tip positioning and a constant flow rate vacuum pump ensure a smooth and efficient washing experience.

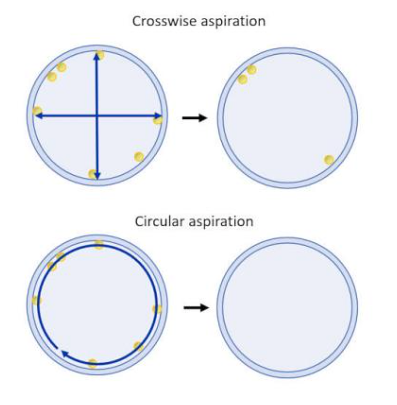

Individual configuration of the washing protocol

Two wash modes are available: Regular wash mode and Superwash mode (also known as “Overflow mode”). When using the regular wash mode, the wash fluid that is dispensing and evacuated follow each other. When using the Superwash mode, the wash fluid that is dispensing and evacuated are conducted simultaneously creating a continuous wash fluid flow throughout the entire well. The Zoom HT supports creating and storing of the 3D tip positioning profile for each plate type and assay. This profile defines the aspirate tip horizontal and vertical positions thereby mapping how the well is aspirated. In addition, the speed with which the tip is immersed into the well is adjustable. Fine-tuning of all the parameters of the wash procedure will allow to wash even loosely adherent cultured cells. The Zoom HT will have residual wash fluid volumes of less than 1 μL/well, this can be achieved when a surfactant is present in the wash fluid.

A unique self-emptying liquid discharge system

The discarded wash fluids are captured by a self-emptying waste trap, which allows uninterrupted processing of large plate batches. Biohazard waste management is supported by the automatic addition of a decontamination solution which is continuously drained from the trap.

Automatic switch of buffer liquids

The Zoom HT is available in 3 different configurations using a one, two or four wash buffer inlet. This is advantageous for applications that require sequential cleaning with different buffers or for an automatic cleaning routine after using the system.

Easy maintenance

The unique design of the dispense manifold eliminates the need for any special cleaning. The aspirate head is maintenance free because of the large aspirate tip diameter. This is combined with a continuous vacuum that reliably prevents any accumulation of reagent residue.

Optional Dispense Module

The optional Dispense Module is an easy-to-install plug-and-play device, is extremely easy to use and requires no calibration. With the addition of a dispense module the Zoom HT Washer becomes an efficient washer-dispenser combination system. The Dispensing Module provides single or dual-channel dispensing of reagents using direct drive and positive displacement syringes to ensure the highest precision and accuracy when dispensing. The dispense module feeds one or two 8- or 16-way manifolds for 96 and/or 384 well microplates

Designed for reliability

The continuous addition of antifoam reagent to the liquid waste trap, and the ability to optimize dispense position and speed, make the Zoom HT ideal for handling problematic reagents. Liquid level sensors alert the user if the reagent bottle is empty or the waste container full. In addition, protocols can be protected from unwanted modification using the administrator mode.

TECHNICAL DETAILS (ZOOM HT WASHER)

Wash head: 96 channel wash head for fast processing of 96 and 384 well microplates

Microplates: 96 well plates and strips, 384 well; Dimensions according to ANSI SLAS

Stacker: One-rail design connecting wash, dispense, and storage positions in short distance on one level

Dispense manifolds: 8-way and 16-way manifolds available

Dispense manifold ports: 2 in direct proximity to wash head for immediate dispensing after aspiration

Syringe size: 2 x 10 mL, separate channels

Dispensing technology: Positive displacement

Dispense speeds: 1-3

Number of reagents: Up to 2

Dispense volume: 5-300 µL

Dispense accuracy: <1% typical @100 µL

Dispense precision: CV ≤1% @ 200 µL

Dimensions (W x D x H): 168 x 405 x 226 mm

Weight: 88.5 kg

Liquid path materials: Glass, Teflon®, Kel-F

Operating temperature: 15° to 35°C

Power Supply: Input: 100-240 VAC ±10%, 50/60 Hz – Output: 24 VDC / 3.75 A